Tariff Tremors: How Small Businesses Are Bearing the Brunt of Trump's Trade War

Business

2025-02-14 17:19:27Content

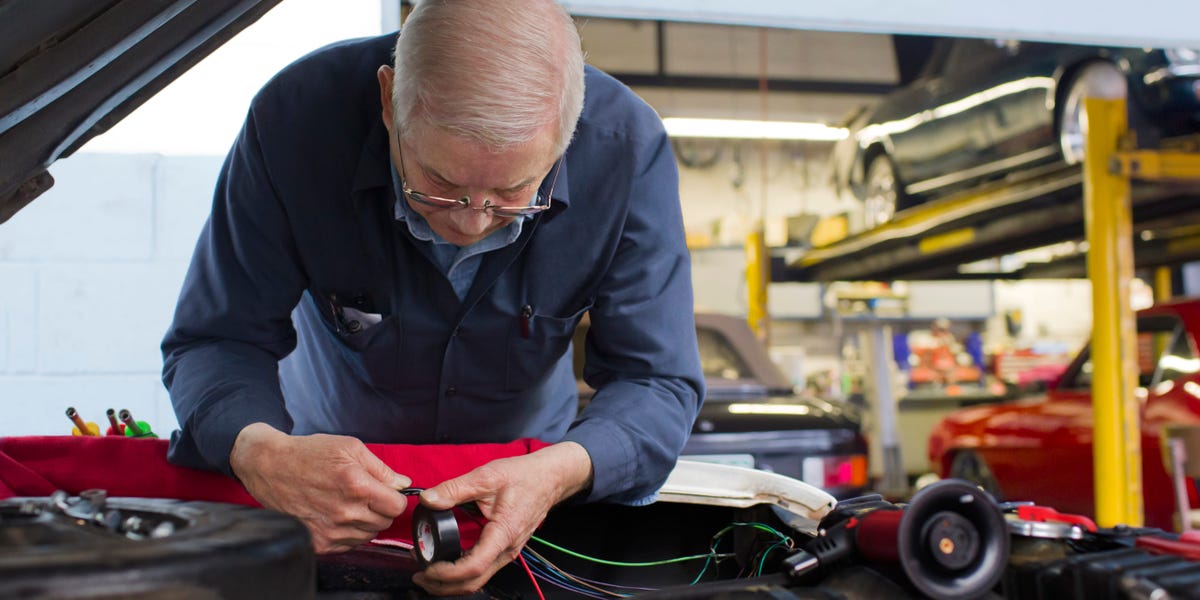

The Cost of American Manufacturing: A Rising Tide of Expenses

American-made products are experiencing a significant surge in production costs, creating challenges for manufacturers and consumers alike. As global economic dynamics shift and domestic manufacturing faces increasing pressures, the price tags on homegrown goods are climbing at an unprecedented rate.

Multiple factors are driving this trend. Rising labor costs, escalating raw material prices, and complex supply chain disruptions are converging to make domestic production more expensive. Manufacturers are grappling with higher wages, stricter regulations, and the need to invest in advanced technologies to remain competitive.

The ripple effects are profound. Consumers are witnessing higher prices across various sectors, from automotive and electronics to clothing and household goods. Small businesses and large corporations are both feeling the pinch, forcing many to make difficult decisions about pricing strategies and production methods.

While these increased costs pose challenges, they also highlight the resilience and adaptability of American manufacturing. Companies are innovating, streamlining operations, and seeking more efficient production techniques to mitigate the financial strain.

As the landscape of domestic manufacturing continues to evolve, one thing remains clear: the journey toward maintaining competitive, high-quality American-made products is becoming increasingly complex and costly.

The Rising Tide of Domestic Product Pricing: A Deep Dive into American Manufacturing Costs

In an era of economic uncertainty and global market shifts, the landscape of American manufacturing is undergoing a profound transformation. The intricate web of economic policies, trade dynamics, and production challenges is reshaping the cost structure of domestically produced goods, creating a complex narrative that extends far beyond simple price tags.Unraveling the Economic Puzzle: Why American-Made Products Are Becoming More Expensive

The Complex Ecosystem of Manufacturing Costs

The contemporary manufacturing environment in the United States represents a sophisticated interplay of multiple economic factors. Raw material procurement has become increasingly challenging, with global supply chain disruptions driving unprecedented volatility in input costs. Manufacturers are confronting a multifaceted landscape where traditional cost-management strategies are being systematically dismantled by external economic pressures. Technological investments, while critical for maintaining competitive edge, are simultaneously driving up production expenses. Advanced robotics, artificial intelligence integration, and sophisticated quality control mechanisms demand substantial capital investments, which inevitably translate into higher product pricing structures.Labor Dynamics and Wage Pressures

The American workforce is experiencing a remarkable transformation, characterized by increasing labor costs and evolving skill requirements. Skilled manufacturing workers command higher compensation packages, reflecting the growing complexity of industrial processes and technological sophistication required in modern production environments. Demographic shifts and generational workforce transitions are further complicating labor dynamics. Younger generations demonstrate different workplace expectations, demanding higher wages, more flexible working conditions, and comprehensive benefits packages that significantly impact overall production costs.Regulatory Compliance and Economic Policy Implications

Stringent environmental regulations, workplace safety standards, and complex tax structures contribute substantially to the escalating costs of domestic manufacturing. Each regulatory requirement represents an additional layer of financial complexity that manufacturers must navigate, ultimately influencing product pricing strategies. Trade policies and tariff mechanisms create additional economic pressure points. The intricate dance of international trade negotiations introduces unpredictability into the manufacturing ecosystem, compelling domestic producers to build financial buffers that protect against potential economic volatility.Technological Innovation and Competitive Strategies

Cutting-edge technological innovations are simultaneously a challenge and an opportunity for American manufacturers. While advanced technologies require significant upfront investments, they also offer potential long-term efficiency gains and productivity improvements. Artificial intelligence, machine learning, and advanced robotics are reshaping production methodologies, creating a dynamic environment where technological adaptation becomes a critical competitive differentiator. These technological transformations demand continuous investment and skill development, further contributing to the complex cost structure of domestic manufacturing.Global Market Interconnectedness

The modern manufacturing landscape is inherently global, with intricate interconnections between domestic and international economic systems. Currency fluctuations, geopolitical tensions, and international trade dynamics create a volatile environment that directly impacts production costs and pricing strategies. Manufacturers must develop sophisticated risk management approaches that can effectively navigate these complex global economic interactions. The ability to anticipate and adapt to rapidly changing market conditions has become a critical competency for sustainable domestic production.RELATED NEWS

Business

Career Pivot: Boomers Ditch Boardrooms for Blue-Collar Grit and Side Hustle Survival

2025-03-09 08:01:01

Business

Bitcoin Bombshell: Sacks Reveals Potential $16 Billion Government Loss in Crypto Liquidation Saga

2025-03-09 03:32:23

Business

Strategic Shift: Amy Corcoran Tapped as Alpha Omega's New Business Development Leader

2025-02-24 08:29:07